In order to enhance technological innovation and transformation capabilities, realize process optimization and improve production efficiency, and ensure the progress of new product development. Dellon Technology recently held the 2023 semi-annual product technology achievement evaluation meeting, which was attended by the evaluation committee composed of senior leaders of the company, heads of technical departments, heads of sales, as well as technical research and development and other personnel.

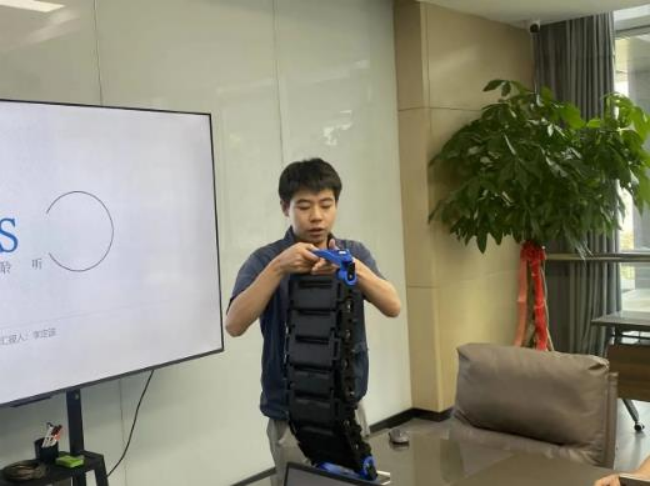

At the meeting, technical R&D personnel took to the stage to demonstrate product technology achievements. The main products on display this time were multi-channel pulsed eddy current detectors, DLU22A low-frequency ultrasonic detectors and in-service butt weld tracking systems. After listening to the technical summary report of the technical research and development personnel, and after questioning and discussion, the members of the evaluation committee unanimously believed that the technical results of the products developed by Dellon in the first half of the year were stable in performance and mature in process, and it was recommended to speed up the promotion and application.

The following is Dellon Technology’s product display (part) in the first half of 2023

Multi-channel pulse eddy current detector

Product background: Compared with traditional corrosion non-destructive testing methods, Dellon DPEC-17 pulse eddy current detector does not need to remove the outer coating of the pipeline and the inspected equipment does not need to be stopped, which can significantly improve detection efficiency and reduce detection costs. However, the detection range of a single probe is limited. In order to further improve detection efficiency and adapt to market demand, Dellon company has developed an array-type pulse eddy current detector, which is mainly aimed at rapid corrosion screening of large tanks and large-diameter industrial pipelines, solving the market pain points of small coverage area and low detection efficiency of a single probe.

Features:

①The probe adopts electronic focusing technology, which has higher spatial resolution of local corrosion defects, different probes do not affect each other, greater defect identification, and stronger anti-interference ability.

②It is not sensitive to the shape of defects and can detect wall thickness corrosion or other thickness thinning defects of metal components with covering layers (thermal insulation layer, cold insulation layer, protective layer, etc.)

③Fully sealed IP64 dust-proof and splash-proof design, silicone sheath anti-drop and anti-vibration design, more suitable for use in harsh working conditions.

DLU22A low frequency ultrasonic detector

Product background: Low-frequency ultrasonic testing instrument, mainly used to measure the sound intensity in the 40kHz±2kHz frequency range in the environment. In industrial environments, invisible and inaudible fault sounds such as leakage, internal leakage, partial discharge, etc. can be measured with this product and converted into audible audio. Simply put, it converts invisible and inaudible fault sounds into visible and audible sounds, providing an effective method for troubleshooting.

Features:

①Lightweight and portable, non-slip hand grip, ergonomic design, can be held with one hand

②3.5-inch high-brightness color screen

③Super long standby, 2 hours of charging, >15 hours of standby

④Laser positioning, infrared temperature measurement

⑤LEMO interface, external sensor channel

At the end of the meeting, Mr. Han, the chief engineer of Dellon Technology, said to the R&D staff: New technology is the soul of new products. It is necessary to clarify R&D thinking and paths, especially in the field of non-destructive testing. We must jump out of conventional thinking and pay attention to the development of smart products. Research and development should take the road of energy conservation, low carbon, environmental protection and re-creation. Product research and development must be practical and fast. We must base ourselves on the market and improve product performance and reliability as the current focus of research and development, and do a good job in secondary research and development, increase the subsequent improvement and upgrading of products, improve product quality and simplify processing processes.

Mr. Han, Chief Engineer of Delang Technology

In the future, Dellon Technology will continue to improve ours products, continue to enhance product technology levels, use innovative research and development to enhance the company's core competitiveness and sustainable development momentum, and build the company's core technological advantages.