Against the backdrop of global energy transformation and environmental protection, wind turbines, as an important component of renewable energy, are developing at an unprecedented rate and have become an important force in promoting the green energy revolution.

Among these, direct-drive wind turbines, as a new type of wind power generation technology, can well meet the power generation requirements of large-scale wind power systems due to their advantages such as low mechanical loss, high operating efficiency, and low maintenance costs. They have become another important type of wind turbine after doubly-fed induction wind turbines and are gradually being put into use.

However, in the process of wind power generation, the complexity of the internal structure of direct-drive wind turbines and the presence of strong magnetic fields pose significant challenges to inspection work.

Direct-drive wind turbines commonly use permanent magnet synchronous generators, which have a large number of magnetic poles (over 90), resulting in relatively large generator size and weight. Furthermore, permanent magnet materials are susceptible to demagnetization under extreme conditions (such as high temperature, vibration, and impact). Once the permanent magnet material is demagnetized, it will seriously affect the generator's performance and may even cause the equipment to malfunction. The cost of replacing and repairing permanent magnet materials is also relatively high. Therefore, improving the maintenance efficiency of large wind turbine equipment, shortening downtime, and reducing maintenance and inspection costs have become urgent priorities for the wind power industry.

Case Background

A wind power plant using commercially available industrial endoscopes to inspect direct-drive wind turbines frequently encountered difficulties due to strong magnetic fields, making normal inspection challenging. The tungsten filament inspection wires and stainless steel camera housings of conventional industrial endoscopes are susceptible to magnetic attraction in strong magnetic fields, leading to wire distortion, blurry images, and even damage, severely impacting the accuracy and safety of the inspection.

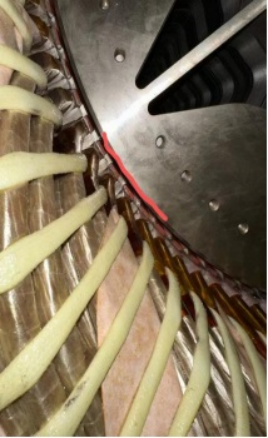

Red line location: Internal testing entrance

Therefore, the user contacted us to customize an industrial endoscope system that could effectively resist magnetic fields and prevent magnetic attraction, in order to meet the inspection needs of the confined spaces inside a direct-drive generator.

After in-depth communication with the customer to understand their specific testing requirements for wind turbine motors, including the motor model, internal structure, and magnetic field strength, Dellon's technical team designed and developed a customized industrial endoscope system that uses special anti-magnetic materials for the inspection cable and camera housing.

This industrial endoscope has the following features:

1.Excellent anti-magnetic properties: The special material is a non-magnetic material that can maintain stable physical and chemical properties in strong magnetic fields, effectively preventing the detection line from being attracted or distorted.

2.The high-strength and lightweight special anti-magnetic material has a high strength-to-weight ratio, making the detection line both lightweight and durable, facilitating flexible operation in confined spaces.

3.Corrosion and Wear Resistance: It possesses excellent corrosion and wear resistance, allowing for long-term use in harsh working environments without easily being damaged.

4.The user performed the inspection using a customized Dellon GX industrial endoscope (probe outer diameter 2.8mm (housing made of special anti-magnetic material), inspection cable length 2 meters (made of special anti-magnetic material).

GX Industrial Endoscope

On-site working conditions

The technicians maneuvered the inspection equipment into the confined space inside the wind turbine motor, conducting comprehensive, multi-angle inspections and identifying several fault points. During the inspection process, the special anti-magnetic design of the equipment ensured stable operation in a strong magnetic field environment and provided robust external protection against external impacts. Based on the identified fault points, wind farm maintenance personnel will take appropriate measures to maintain the equipment, extending the service life of the wind turbine motor and ensuring production safety.

User reviews

This GX industrial endoscope, customized with special anti-magnetic materials, has demonstrated excellent anti-magnetic performance in practical testing, successfully solving the problem of inspecting confined spaces with strong magnetic fields inside wind turbine motors. Subsequently, inspections can be carried out systematically according to the relevant procedures, without worrying about magnetic interference or repeatedly verifying the validity of the results. This shortens the inspection cycle and reduces repair and replacement costs caused by improper inspections.

With over twenty years of experience in the field of non-destructive testing, Dellon Technology's industrial endoscopes and other products can be widely used in the wind power industry. They help to detect internal faults such as gearbox and motor coil baffle misalignment and displacement more quickly and effectively, minimizing downtime, optimizing maintenance plans, and shortening maintenance cycles. These diverse wind power inspection solutions safeguard the safe and stable supply of wind energy.