●Using the rare-earth high-strength permanent magnet wheel, even if there is an unexpected power failure, it will not fall from the detected surface. It can perform horizontal, vertical and inverted multi-attitude motions on the surface of ferromagnetic components.

●Intensive and accurate scanning of suspected corrosion areas quantifies wall corrosion.

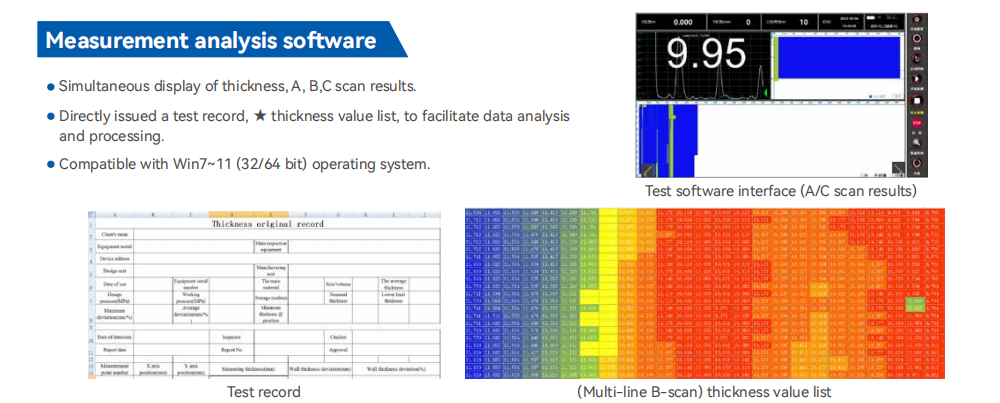

●Standard A, B, and C scan displays make area-based thickness scan results easy to see at a glance.

●Equipped with video camera, can timely observe the video situation of the inspected surface.

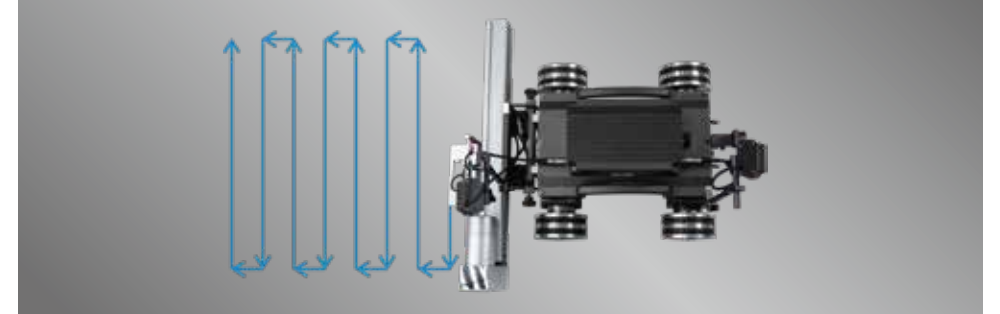

●The remote control (handle) is used to remotely control the scanning track, and the scanning track can be preset to do automatic scanning.

This system does not need scaffolding, no need to polish the antiseptic layer, without any coupling agent. It can realize rapid detection of high altitude wall thickness corrosion through remote control system.

Functional Features

Magnetic crawler and host

lIntegrated front-view and rear-view dual cameras: the inspection position and inspection route of overhead components can be monitored and adjusted in real time on the ground, ensuring a controllable inspection trajectory.

lStrong magnetic suction, heavy load, high safety: the use of rare earth high-strength permanent magnetic wheel, can be firmly adsorbed on the surface of ferromagnetic materials (vertical upward movement load up to 16kg (most of the testing instruments ≤ 6kg), when stationary by manpower is also difficult to pull down), that is to say, even if the accidental power failure will not fall. It is also equipped with a fall prevention device to prevent accidental falls.

lVariety of movement postures: It is safe to travel on the surface of ferromagnetic materials in different postures such as vertical, horizontal (above and below), inclined and inverted.

lHigh motion precision: adopting high-power four-motor four-wheel drive mode, it can accurately advance and retreat and steer; equipped with high-precision encoder can realize accurate to millimeter-level programmed step detection, and it can accurately set the step spacing and stroke of longitudinal advance and retreat.

lFlexible and ingenious body design: compact size, small turning radius; with a handle can be easily moved, placed, recycled.

lMotion Oriented Guidance Function: With macro video surveillance function, it can observe the video situation of the inspected surface in time.

lWith distance positioning (positioning error ≤30mm), (optional) defect marking function, convenient to repeat the observation of suspicious areas.

lProfessionally designed "scanning clamping mechanism" ensures stability of travel and probe coupling.

lWith special cables, explosion-proof plugs, and leakage protection devices, it has high electrical safety.

lThe EAMT and other circuit modules on the robot body are sealed in a protective box to prevent water, iron filings, and other foreign objects from entering.

lThe portable cable rack integrates a removable, high-brightness (sunlight-visible), high-definition industrial control panel that takes into account the operating environment and conditions of use in the field.

lFully programmed motion control and parallel synchronous processing: ultrasound data, image data and travel distance data can be acquired at the same time, which can ensure the synchronization and accuracy of the data and records, and greatly improve the work efficiency.

lThe mainframe operating software has functional modules for human-computer interaction, user management, parameter input, report generation and output/printing, data maintenance and backup, operation logs, online help and so on.

EAMT thickness measurement

lBreakthrough the limitations of traditional piezoelectric ultrasonic thickness measurement, equipped with electromagnetic ultrasonic thickness measurement probe, for wall thickness corrosion to do rapid screening and localization.

lNo need for surface polishing, penetration of anti-corrosion coating and rust, and no need for coupling agent.

lThickness measurement can penetrate surface corrosion, paint, corrosion protection and other coatings up to 4mm thick. The thickness value of metal objects displayed by the instrument does not need to consider the calculation of coating thickness.

lMeasurement non-perpendicularity (transducer/probe to the normal line of the object to be tested) is up to ±25°, which requires less perpendicularity after the probe is placed.

lThe thickness measurement results can be displayed in digital value form, A-scan form, time-based B-scan image form, and distance-based (encoder) B-scan image form.

lUsing expert intelligent algorithm, there are three thickness measurement modes: automatic mode, single gate manual mode (single peak method), double gate manual mode (peak to peak method).It greatly reduces the influence of human factors and simplifies the operation steps.

lBuilt-in database of basic material S-wave speed, and can customize S-wave speed value.

Technical parameters | |

Magnetic crawler and host | |

Host | CPU ≥ i5/4GHz quad-core, high-end industrial flat panel, high brightness HD display 10.6 inch (can be customized), standard 240G high-speed hard disk (expandable), IPX3 protection. |

Control cable (crawling distance) | 15, 30m (can be customized). |

Motion path | Linear (longitudinal continuous motion of the body + transverse scanning arm does not move), zigzag (longitudinal continuous motion of the body + transverse scanning arm continuous round-trip), bow type (longitudinal stepping of the body + transverse scanning arm continuous round-trip). |

Longitudinal movement | Stepping speed 5~200mm/s, can quickly travel to the detection position or back to the ground; the ability to cross the barrier ≤3mm |

C scanning bracket/transverse encoder arm | Left and right total travel 300mm (can be customized), speed 0-80mm/s |

Minimum radius of curvature of the surface of the workpiece R | ≥0.75m when there is no residual height, ≥1.5m when there is residual height such as weld seams. |

Crawler body (with embedded EMAT module) | L350×W330×H230mm, weighing about 17kg, able to pass through a hole of Φ450mm smoothly. |

Control handle | L220×W145×H60mm, 3.5-inch 640×480 pixel touch display, weight about 0.4kg |

Power supply | Single-phase AC100~240V, 50/60Hz, power consumption ≤200VA |

Temperature | -10℃~+50℃ |

Humidity | ≤85%R.H |

EAMT thickness measurement unit | |

Thickness measurement | Accuracy 0.04mm, Range 2~120 mm (Steel) |

Work clearance / lift-off | ≤4mm |

Measurement non-perpendicularity (normal to the transducer/probe relative to the object under test) | ±25° |

Sound speed range | 1000~9999 m/s |

Adjustment increment | 1 m/s |

Gate function | Automatic gate, manual single gate, manual double gate |

Video monitoring | Both the front and back vision dual cameras, dynamic and static pixels are 3 million /2304×1296 |

Electromagnetic ultrasound probe | Weak or less permanent magnets, the magnetic suction≤15N, circular Φ30× high 44mm, weight≤80g |

Working temperature | -10~+50℃ |

Item | Name | Quantity&Unit | Remark |

1 | Test host(PC and Software ) | 1 Set | 10.6 inch screen |

2 | DMC200D magnetic crawler (video module included) | 1 Set | / |

3 | EMAT Thickness Measurement Module | 1 Set | / |

4 | C-scan frame/transverse grating arm | 1 Pcs | 300mm |

5 | Defect marking device | 1 Pcs | Optional |

6 | Cable unit (Power supply, Cable Winding Rack, Control cable) | 1 Set | 15m、30m |

7 | Safety rope drop preventer | 15m/30m | / |

8 | Other accessories (magnetic dismantling pads, etc.) | 1 Set | / |