●Inspections can be done when the equipment is running (High temperature, low temperature, materials in the equipment etc.)

●Materials that was detected: Detection of remaining wall thicknesses ferromagnetic metal material such as carbon steel, low alloy steel.

●It can also detect the remaining wall thicknesses of stainless steel, aluminum alloy and other non-ferromagnetic metal materials.

●Cladding materials: Non-conductive, non-magnetic materials( asbestos, foam etc.), metal mesh, iron, aluminum and other protective layer.

●AC/DC hybrid power supply, built-in rechargeable lithium battery continually working more than 8 hours.

●Fully sealed IP64 anti-dust and anti-splash design, silicone sheath anti-drop and anti-vibration design, more suitable for harsh working conditions.

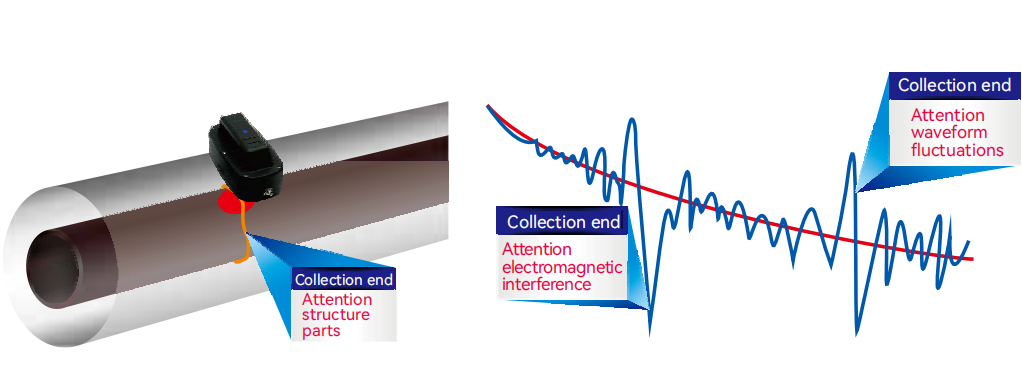

The equipment can be used for in-service inspection of metal pipe wall thickness outside the cladding layer, it instead of traditional sinusoidal current incentives to pulse current, pulse magnetic field outside the conductor, the conductor in the pulsed eddy current sensor, by measuring the attenuation process of pulsed eddy current electromagnetic field, to assess the degree of corrosion of pipe wall thickness compared with the traditional NDT methods of corrosion, without removing pipe outsourcing cladding on the inspection equipment without stopping, can significantly improve the detection efficiency, and reduce the test cost.

Functional features

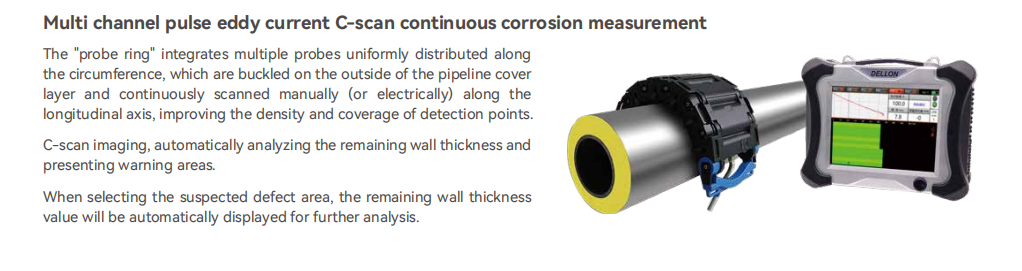

The probe adopts electronic focusing technology, which has higher spatial resolution, greater recognition, and stronger anti-interference ability for local corrosion defects.

Not sensitive to the shape of defects, it can detect the wall thickness corrosion or other thickness reduction defects of metal members "with cover layer (insulation layer, cooling layer, protective layer, etc.)"

Extended function

Technical parameters | ||

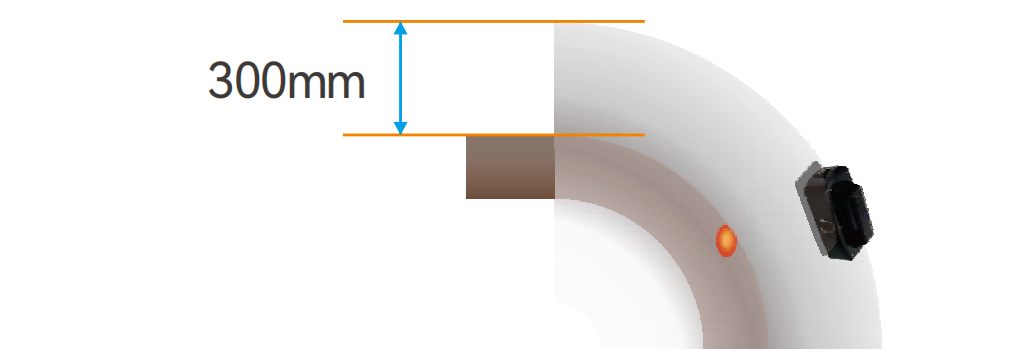

The max thickness of cladding layer | With stainless steel or aluminum protective layer ≤300mm,with iron protective layer ≤150mm | |

The max detection of wall thickness | 2~100mm | |

Diameter of the pipe | ≥21mm | |

The thickness of metal protective layer | ≤1mm | |

Repeated detection accuracy | 0.02 | |

Corrosion defect detection sensitivity | 5% (volume ratio) | |

Measuring speed | 15~0.5 time/s (reducing with the increasing measured wall thickness) | |

The length of probe cable | 5m, 30m (optional) | |

Built-in rechargeable Lithium battery | Continually working more than 8 hours. | |

Size and Weight | Host: L346×W278×H136mm 7kg | Type P1/small probe: L106×W61×H52mm 0.5kg |

Type P2/medium probe: L148×W73×H192mm 1kg | Type P3/large probe: L186×W95×H97mm 1.5kg | |

Temperature of the tested medium | -200~800℃ | |

Working Temperature | -10℃~50℃ | |

Humidity | ≤85%R.H | |

Adapter power supply | Single phase AC100~240V、50Hz±1% | |

Power Dissipation | ≤100VA | |

Parameters of probe | ||

The max thickness of cladding layer | With stainless steel or aluminum protective layer ≤100mm,with iron protective layer ≤80mm | |

The max detection of wall thickness | 3~35mm | |

Diameter of the pipe | ≥140mm | |

The thickness of metal protective layer | ≤1mm | |

Repeated detection accuracy | 0.01 | |

Corrosion defect detection sensitivity | 5% (volume ratio) | |

Measuring speed | 15~0.5 time/s (reducing with the increasing measured wall thickness) | |

The length of probe cable | 5m, 30m (optional) | |

Size and Weight: | Six-channel array probe:L687.5×W230×H65mm,8.15kg | |

Item | Name | Quantity&Unit | Remark |

1 | DPEC-17 Host (including data cable, charger) | 1 Set | Standard |

2 | Carbon steel probe (C.S: smaller, medium, larger, contains a piece of 5m connection cable) | 1 Group | Standard |

3 | Stainless steel probe (S.S: smaller, medium) | 1 Group | Optional |

4 | Carbon steel bare tube high resolution probe (including handle) | 1 Piece | Optional |

5 | Stainless steel bare tube high resolution probe | 1 Piece | Optional |

6 | 30m probe cable | 1 Set | Optional |

7 | Probe extension rod | 1 Piece | Optional,3m or 5m |